Instead of producing a solid core, reverse circulation drilling, also known as reverse air drilling, produces microscopic rock pieces (chips) (core). It is significantly faster than diamond drilling and requires much larger equipment, such as an air compressor with a huge capacity.

The reverse circulation rod's design, they have a double wall, which permits drilling to recover samples through the middle of them. The most common sweeping agents, air or water, enter the column through the bar's sides or a lateral connection (a swivel), which connects to the annular area between the outer sleeve and the inner tube. Descending to the bottom of the hole the samples that are being extracted, are guided toward the center of the drilling instrument and evacuated to the surface.

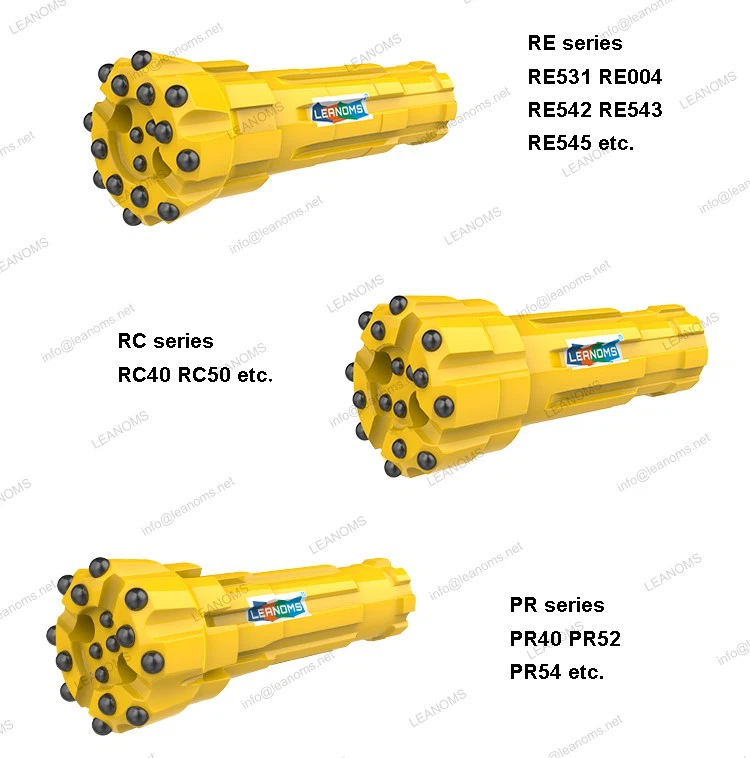

In that the Reverse Circulation Drill Bit are brought back to the surface inside the rods, RC drilling is comparable to air core drilling in this regard. The drilling mechanism consists of a tungsten-steel Reverse Circulation Drill Bit being driven by a pneumatic reciprocating piston known as a hammer. With the help of considerably larger rigs and equipment, RC drilling frequently achieves depths of up to 500 meters. Large air compressors dry the rock out before the advancing drill bit, which is how RC drilling generates dry rock chips in the optimum situation. Although RC drilling is slower and more expensive than RAB or air core drilling, it produces better penetration, is less expensive than diamond coring, and is thus used for the majority of mineral exploration work.

Air is forced down the rods to create air lift of the water, and the inner tubes within each rod are broken up to accomplish reverse circulation. After passing through the bell at the top of the hole, it goes via a sample hose that is fastened to the top of the cyclone.

Before falling through a bottom aperture and being collected in a sample bag, the drill cuttings circle the inside of the cyclone. To drill into shale and abrasive rock, Reverse Circulation Drill Bit with a diameter of 5-8 inches (12.7-20.32 cm) are most frequently employed. These Reverse Circulation Drill Bits also contain spherical metal "buttons" that protrude from the bit.

RE531 Reverse circulation drill bit and shroud

| Diameter | No x Button diameter, mm | Button angle° | Flushing holes | Shroud Diameter | Weight(KG) | Part Number | ||

| mm | Inch | Gauge Buttons | Front Buttons | |||||

| 86 | 3 2/5 | Φ12*6 | Φ12*5 | 35 | 2 | 84 | 6.0 | RE531-86 |

| 89 | 3 1/2 | Φ12*8 | Φ12*5 | 35 | 2 | 87 | 6.1 | RE531-89 |

| 95 | 3 3/4 | Φ12*8 | Φ12*6 | 35 | 2 | 93 | 6.3 | RE531-95 |

| 102 | 4 | Φ12*8 | Φ12*6 | 35 | 2 | 100 | 6.5 | RE531-102 |