DTH Hammers and chisels have been used by humans since the Stone Age to break up rocks. This page outlines the historical concepts and innovations that were used to incorporate hydraulic Rock Drilling Tools.

There are two strategies that combined: During the Industrial Revolution, blast hole drilling was used in mining and tunneling as well as deep drilling for water, gas, and oil wells.

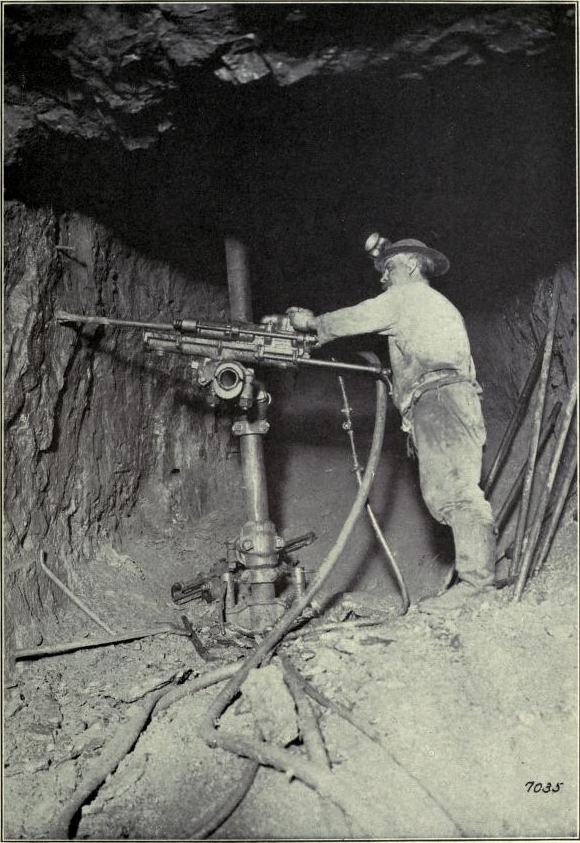

Pneumatic Rock Drills in the 19th century

Before the invention of the first steam-powered rock drills in the 1850s, most diggings were done by hand. They were created to drill blast holes. Some novel devices, like as air compressors and air-driven percussion drills, were employed for the first time during the construction of the Hoosac tunnel.

The DTH hammer drill by Ingersoll in 1871 is often mentioned as a milestone in percussion drilling. A chisel is accelerated into the hole and turned automatically. The apparatus was small enough to be transported by workers and had an automatic feed.

The invention of a valveless DTH hammer drill dates back to 1872 when C. J. Ball filed a patent that employed a piston as a valve: The piston will open channels connecting its surfaces to the exhaust and the fluid supply when it reaches a specific point. By doing this, pressure will be applied on one side while being released from the other. This will seal the channels and cause the fluid to expand, accelerating the piston even further until it reaches the opposite side and reversing the pressures. This concept is still used in pneumatic Down-The-Hole (DTH) Hammer drills but cannot be used for hydraulic DTH Hammer drills, as the expansion is part of the mechanism and not available for hydraulics.

Well drilling in the 19th century

Even until the beginning of the 20th century, well drilling in hard rock was done by cable tool percussion drilling: A chisel mounted on a cable is dropped into the borehole and pulled up again. This method is known for thousands of years and is still used in developing countries.

For drilling soft rocks, fishtail drag bits were used in rotary drilling.

There are some inventions at the End of the 18th century which proposed a drive mechanism at the end of the drill driven by the drilling fluid, like the turbine drive for diamond drill bits from 1873 by Christopher G. Cross.

The history of Down-the-Hole (DTH) rock drilling tools is closely tied to the evolution of drilling technology and the demand for efficient and effective methods of rock penetration in various industries. Here is a brief overview of the historical development of DTH rock drilling tools:

Early Mechanical Drilling:

Before the invention of specialized DTH tools, early mechanical drilling methods involved manual labor using picks, chisels, and hammers. These methods were labor-intensive and limited in terms of depth and efficiency.

Introduction of Compressed Air Drilling:

The use of compressed air in drilling operations gained prominence in the mid-19th century. Compressed air drills improved efficiency compared to manual methods, allowing for deeper and faster penetration into rock formations.

Pneumatic Rock Drills:

The late 19th century saw the development of pneumatic rock drills, powered by compressed air. These drills were the predecessors to modern DTH drilling tools and were an important step toward mechanized rock drilling.

Early DTH Concepts:

The concept of Down-the-Hole drilling started to emerge in the early 20th century. Innovations included the design of hammers that could deliver powerful blows directly to the drill bit at the bottom of the borehole.

Post-World War II Advances:

After World War II, there was a significant push for technological advancements in various industries, including mining and construction. This era saw improvements in materials, manufacturing processes, and the development of more powerful DTH drilling equipment.

Introduction of DTH Hammers:

The actual DTH hammer, a critical component of the DTH drilling system, was developed in the mid-20th century. These hammers utilized compressed air to deliver rapid, powerful blows to the drill bit, allowing for efficient rock penetration.

Evolution of Drill Bits:

Concurrently, advancements were made in the design and materials of drill bits used in DTH drilling. Tungsten carbide inserts and later diamond inserts were incorporated for enhanced durability and cutting efficiency.

Application in Mining and Construction:

DTH drilling tools found widespread application in mining and construction during the latter half of the 20th century. The efficiency and versatility of DTH drilling made it a preferred method for various drilling operations.

Technological Innovations:

Ongoing technological innovations, including improvements in hammer design, materials, and manufacturing processes, have continued to enhance the performance and reliability of DTH rock drilling tools.

Modern DTH Drilling Systems:

Today, DTH drilling systems are widely used across industries, including mining, construction, geotechnical exploration, and water well drilling. These systems are characterized by advanced engineering, high-powered hammers, and precision-manufactured drill bits for optimal rock penetration.

The history of DTH rock drilling tools reflects a continuous effort to improve drilling efficiency, depth capabilities, and versatility in diverse geological conditions. Ongoing research and development contribute to the evolution of these tools, ensuring their effectiveness in various applications.